You Are Here:Home > Information dynamic

> Industry Trends

News Navigation

What are the main raw materials for formaldehyde free ENF grade environmentally friendly particleboa

source:m.flipfork-official.com Time:2025-11-24

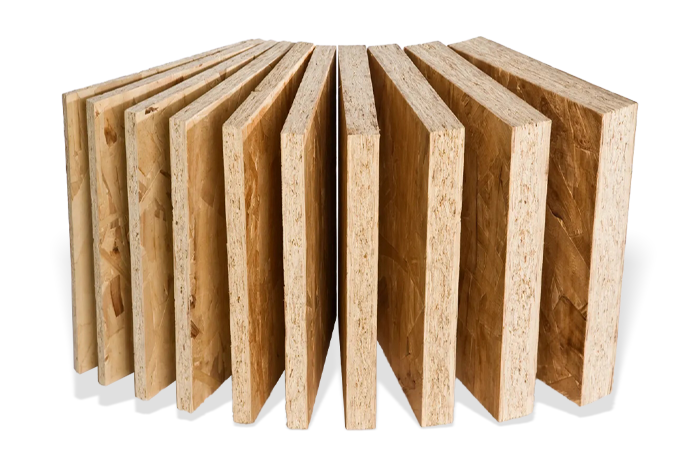

The raw material core of formaldehyde free ENF grade environmentally friendly particleboard is designed around "formaldehyde pollution free, structurally stable, and environmentally compliant". It mainly consists of three categories: wooden raw materials, formaldehyde free adhesives, and functional additives. The selection of each type of raw material directly affects the environmental friendliness, physical properties, and applicable scenarios of the board, as follows:

1、 Core raw material: Wood raw material (main body of board, accounting for 85% -95%)

As the skeleton of the board, wooden raw materials need to meet the requirements of "low formaldehyde, easy processing, and good adhesion". The mainstream types include:

1. Wooden veneer (core substrate)

Tree species: Natural soft/neutral wood such as pine (white pine, red pine), poplar, fir, birch, etc. These types of wood have low formaldehyde emissions (close to the baseline of natural wood), good fiber toughness, easy cutting into uniform slices, and stable structure after bonding.

Processing requirements: After peeling, slicing, drying (moisture content controlled at 8% -12%), and screening, the logs are processed into different specifications of planing pieces (fine planing pieces on the surface layer and coarse planing pieces on the core layer) to ensure uniform density of the board and avoid internal voids.

2. Wood processing scraps (environmentally friendly recycled materials)

Source: Wood scraps from furniture and flooring factories (such as sawdust, shavings, and broken wood blocks), recycled building formwork materials (requiring impurity removal and disinfection treatment), in line with the environmental protection concept of "resource recycling".

Processing standard: Impurities such as metal and plastic must be removed, and then sterilized and insect treated by high-temperature drying (120-150 ℃), while ensuring no mold or odor, to avoid affecting the environmental protection and durability of the board.

3. Straw/bamboo chips (biomass substitute raw materials, some products)

Applicable scenarios: The main focus is on "fully bio based and environmentally friendly" boards, which will add biomass materials such as wheat straw, corn straw, bamboo chips (accounting for ≤ 30%) to replace some wood shavings.

Advantages: Straw/bamboo chips themselves do not contain formaldehyde, and have a wide range of sources and low costs. At the same time, they can improve the hardness and wear resistance of the board; But it needs to be paired with specialized formaldehyde free adhesive to avoid weak bonding.

2、 Key raw materials: formaldehyde free adhesive (environmentally friendly core, accounting for 5% -10%)

Adhesive is the core determining the "formaldehyde free" property of the board, which must be completely free of formaldehyde and meet the bonding strength standards. The mainstream types include:

1. MDI adhesive (isocyanate adhesive, the most mainstream)

Characteristics: It does not contain formaldehyde and forms a stable polymer after curing. It has high bonding strength (2-3 times that of urea formaldehyde resin adhesive) and is resistant to water, moisture, and corrosion. It is suitable for humid environments such as kitchens and bathrooms.

Applicable scenarios: Adhesives for the vast majority of formaldehyde free ENF grade particleboard, especially suitable for furniture and whole house customized boards.

2. Biobased formaldehyde free adhesive (natural and environmentally friendly)

Raw material sources: natural biomass such as soy protein, starch, lignin, etc., processed through modification, completely free of chemical synthesis components, and environmentally friendly.

Characteristics: Formaldehyde free, odorless, suitable for environments with high environmental requirements such as children's rooms and hospitals; But the bonding strength is slightly lower than that of MDI adhesive, and the moisture resistance is poor. It is mostly used for indoor dry environment boards.

3. PUR adhesive (polyurethane hot melt adhesive, auxiliary type)

Characteristics: No formaldehyde release, fast curing speed, strong adhesion, and a certain degree of flexibility, which can improve the deformation resistance of the board.

Applicable scenarios: Some thin ENF grade particleboard (such as thickness ≤ 12mm) or decorative substrates are often used in combination with MDI adhesive to optimize processing performance.

3、 Auxiliary raw materials: functional additives (proportion ≤ 3%, optimized performance)

Additives must meet the standards of "formaldehyde free and non-toxic", mainly used to improve the physical properties, moisture resistance, fire resistance, etc. of the board. Common types include:

1. Moisture proof agent

Ingredients: paraffin lotion, zinc stearate, etc., without formaldehyde release, can form a hydrophobic film on the surface of the chip.

Function: Improve the moisture resistance and waterproof performance of the board, avoid expansion and deformation when exposed to moisture, and adapt to humid environments such as kitchens and balconies (moisture resistance level can reach EN 312 D3 level).

2. Curing agent/catalyst

Ingredients: Special environmentally friendly curing agent (such as amine compounds, formaldehyde free), used in combination with MDI glue and PUR glue.

Function: Reduce the curing temperature of the adhesive, shorten the curing time, ensure a firm bond between the planing pieces, and improve the bending strength and nail grip of the board.

3. Flame retardants (optional, special scenarios)

Ingredients: Environmentally friendly flame retardants (such as inorganic flame retardants such as aluminum hydroxide and magnesium hydroxide), free of harmful substances such as halogenated compounds and formaldehyde.

Function: Make the board meet the B1 fire protection standard, suitable for furniture and decorative components in public places such as hospitals, schools, and shopping malls.

4. Antibacterial agents (optional)

Ingredients: Inorganic antibacterial agents such as silver ions and zinc ions, non-toxic, odorless, and non volatile.

Function: To prevent the growth of bacteria such as Escherichia coli and Staphylococcus aureus, suitable for scenarios with high hygiene requirements such as children's rooms, hospitals, and food factories.

5. Deodorizer (auxiliary type)

Ingredients: Natural adsorbent materials such as activated carbon and bamboo charcoal powder, without chemical additives.

Function: Absorb trace odors that may occur during the production process (such as slight odors from adhesives), and improve the comfort of using the board.

4、 The core principles of raw material selection

Environmental priority: All raw materials (especially adhesives and additives) must pass ENF level environmental testing, with formaldehyde emissions ≤ 0.025mg/m 3 and no harmful substances such as heavy metals and VOCs exceeding the standard;

Performance matching: The moisture content and planing specifications of the wooden raw materials need to be adapted to the adhesive to ensure bonding strength; Functional additives need to be added according to the usage scenario (such as adding moisture-proof agents in humid environments);

Compliance: The raw materials must comply with international certification requirements such as GB/T 39600-2021 (ENF grade artificial board standard) and CARB EPA NAF in the United States, and avoid adding hidden materials containing formaldehyde (such as some cheap preservatives).

1、 Core raw material: Wood raw material (main body of board, accounting for 85% -95%)

As the skeleton of the board, wooden raw materials need to meet the requirements of "low formaldehyde, easy processing, and good adhesion". The mainstream types include:

1. Wooden veneer (core substrate)

Tree species: Natural soft/neutral wood such as pine (white pine, red pine), poplar, fir, birch, etc. These types of wood have low formaldehyde emissions (close to the baseline of natural wood), good fiber toughness, easy cutting into uniform slices, and stable structure after bonding.

Processing requirements: After peeling, slicing, drying (moisture content controlled at 8% -12%), and screening, the logs are processed into different specifications of planing pieces (fine planing pieces on the surface layer and coarse planing pieces on the core layer) to ensure uniform density of the board and avoid internal voids.

2. Wood processing scraps (environmentally friendly recycled materials)

Source: Wood scraps from furniture and flooring factories (such as sawdust, shavings, and broken wood blocks), recycled building formwork materials (requiring impurity removal and disinfection treatment), in line with the environmental protection concept of "resource recycling".

Processing standard: Impurities such as metal and plastic must be removed, and then sterilized and insect treated by high-temperature drying (120-150 ℃), while ensuring no mold or odor, to avoid affecting the environmental protection and durability of the board.

3. Straw/bamboo chips (biomass substitute raw materials, some products)

Applicable scenarios: The main focus is on "fully bio based and environmentally friendly" boards, which will add biomass materials such as wheat straw, corn straw, bamboo chips (accounting for ≤ 30%) to replace some wood shavings.

Advantages: Straw/bamboo chips themselves do not contain formaldehyde, and have a wide range of sources and low costs. At the same time, they can improve the hardness and wear resistance of the board; But it needs to be paired with specialized formaldehyde free adhesive to avoid weak bonding.

2、 Key raw materials: formaldehyde free adhesive (environmentally friendly core, accounting for 5% -10%)

Adhesive is the core determining the "formaldehyde free" property of the board, which must be completely free of formaldehyde and meet the bonding strength standards. The mainstream types include:

1. MDI adhesive (isocyanate adhesive, the most mainstream)

Characteristics: It does not contain formaldehyde and forms a stable polymer after curing. It has high bonding strength (2-3 times that of urea formaldehyde resin adhesive) and is resistant to water, moisture, and corrosion. It is suitable for humid environments such as kitchens and bathrooms.

Applicable scenarios: Adhesives for the vast majority of formaldehyde free ENF grade particleboard, especially suitable for furniture and whole house customized boards.

2. Biobased formaldehyde free adhesive (natural and environmentally friendly)

Raw material sources: natural biomass such as soy protein, starch, lignin, etc., processed through modification, completely free of chemical synthesis components, and environmentally friendly.

Characteristics: Formaldehyde free, odorless, suitable for environments with high environmental requirements such as children's rooms and hospitals; But the bonding strength is slightly lower than that of MDI adhesive, and the moisture resistance is poor. It is mostly used for indoor dry environment boards.

3. PUR adhesive (polyurethane hot melt adhesive, auxiliary type)

Characteristics: No formaldehyde release, fast curing speed, strong adhesion, and a certain degree of flexibility, which can improve the deformation resistance of the board.

Applicable scenarios: Some thin ENF grade particleboard (such as thickness ≤ 12mm) or decorative substrates are often used in combination with MDI adhesive to optimize processing performance.

3、 Auxiliary raw materials: functional additives (proportion ≤ 3%, optimized performance)

Additives must meet the standards of "formaldehyde free and non-toxic", mainly used to improve the physical properties, moisture resistance, fire resistance, etc. of the board. Common types include:

1. Moisture proof agent

Ingredients: paraffin lotion, zinc stearate, etc., without formaldehyde release, can form a hydrophobic film on the surface of the chip.

Function: Improve the moisture resistance and waterproof performance of the board, avoid expansion and deformation when exposed to moisture, and adapt to humid environments such as kitchens and balconies (moisture resistance level can reach EN 312 D3 level).

2. Curing agent/catalyst

Ingredients: Special environmentally friendly curing agent (such as amine compounds, formaldehyde free), used in combination with MDI glue and PUR glue.

Function: Reduce the curing temperature of the adhesive, shorten the curing time, ensure a firm bond between the planing pieces, and improve the bending strength and nail grip of the board.

3. Flame retardants (optional, special scenarios)

Ingredients: Environmentally friendly flame retardants (such as inorganic flame retardants such as aluminum hydroxide and magnesium hydroxide), free of harmful substances such as halogenated compounds and formaldehyde.

Function: Make the board meet the B1 fire protection standard, suitable for furniture and decorative components in public places such as hospitals, schools, and shopping malls.

4. Antibacterial agents (optional)

Ingredients: Inorganic antibacterial agents such as silver ions and zinc ions, non-toxic, odorless, and non volatile.

Function: To prevent the growth of bacteria such as Escherichia coli and Staphylococcus aureus, suitable for scenarios with high hygiene requirements such as children's rooms, hospitals, and food factories.

5. Deodorizer (auxiliary type)

Ingredients: Natural adsorbent materials such as activated carbon and bamboo charcoal powder, without chemical additives.

Function: Absorb trace odors that may occur during the production process (such as slight odors from adhesives), and improve the comfort of using the board.

4、 The core principles of raw material selection

Environmental priority: All raw materials (especially adhesives and additives) must pass ENF level environmental testing, with formaldehyde emissions ≤ 0.025mg/m 3 and no harmful substances such as heavy metals and VOCs exceeding the standard;

Performance matching: The moisture content and planing specifications of the wooden raw materials need to be adapted to the adhesive to ensure bonding strength; Functional additives need to be added according to the usage scenario (such as adding moisture-proof agents in humid environments);

Compliance: The raw materials must comply with international certification requirements such as GB/T 39600-2021 (ENF grade artificial board standard) and CARB EPA NAF in the United States, and avoid adding hidden materials containing formaldehyde (such as some cheap preservatives).

Previous:

What are the extended use scenarios of moisture-p…

Next:

Why is it suitable to use odorless E0 grade envir…

Related articles

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell